Source: Eindhovens Dagblad

The Eindhoven supplier Sioux does not hold a garage sale. Director of new business Arnoud de Geus wants to take away that impression, even though the subsidiaries Liteq and Phenom-World were sold within a period of six months. "They were ready for this step and the proceeds, including the profits, we will invest in new companies."

"We are very close to what is emerging in the high-tech region. If the technology has been proven but not developed yet, it can be interesting for us. And when we invest in it we have a long breath. We use our knowledge of soft- and hardware and also of the high-tech world markets to strengthen the development." De Geus explains that Sioux sometimes incorporates new technology into the organization and sometimes turns it into a separate company. "We ourselves are now a broad technology production company. Known for our software, but also as supplier of hardware with our production facilities in Nederweert and Eindhoven. We supply to major high-tech companies such as ASML and FEI and smaller producers of end products. Last year we had a turnover of 60 million euros with 600 people and we are growing fast. Soon we will announce the acquisition of a company in southern Germany, with which we will open a very interesting market."

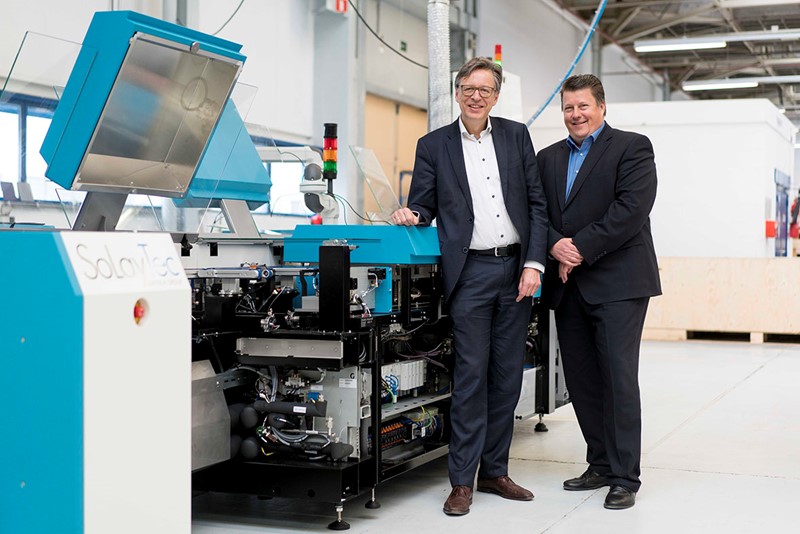

If a new initiative is focused on end products, De Geus chooses to place it within the Sioux Tech Fund in a separate company. "We then provide our knowledge, we produce the parts and take care of the assembly. If they are ready for an exit just like Liteq, Phenom and earlier Fleetlogic, we can take that step. We will remain a supplier. You arrange that during the sale, but the choice for Sioux has to be self-evident because of our technical competence level. This is how we create our own customers with these new companies." Sioux has more irons in the fire, says De Geus. To begin with, MuTracx, which makes machines that use print techniques to apply conductive traces on printed circuit boards. "We successfully started that from a bankruptcy. We already have customers in the United States and Asia and now we also approach manufacturers of that type of printed circuit boards in China. Partly for this purpose, we are setting up a sales office in China." De Geus also mentions Solaytec, which builds machines that use TNO technology to apply an atomic layer of aluminum oxide to solar cells. "That company is running very well and has already put 25 machines in the field." Vexar, which builds conveyor belts with which products can be transported with micron accurancy also has a good chance of success, according to De Geus. "That is a very nice development by our daughter company Sioux-CCM in Nuenen. And we have more where that came from."

De Geus says that the Sioux Tech Fund does not undertake the financing of all these initiatives on its own. "You should know that investments of 20, 30 or 40 million in a company before the first products are sold, are very normal. We want to put in a considerable amount of risk money in this phase. But that is only possible if this is supplemented by, for example, the European Investment Fund (EIF). The Netherlands Rijksdienst voor ondernemen (RVO) is also indispensable for us, just like the Brabant Development Agency (BOM). With joint efforts it is possible to turn good companies, that offer a lot of employment, into a success."