With the rise of 3D printing, production of dental implants has become faster and more automated. The quality assurance needs to follow suit. The current practice is either a manual visual inspection or requires a minutes long scan of the object.

Within this European subsidy project, Sioux has developed and validated a prototype for a 3D scanner with high resolution and high framerate suitable for fast and accurate measurements of the printed dental implants. The prototype consists of optics, electronics, algorithms and software implementation. The calibration algorithms and laser-detection algorithms are custom developments for the event-camera. Refinement of the demonstrator is currently ongoing.

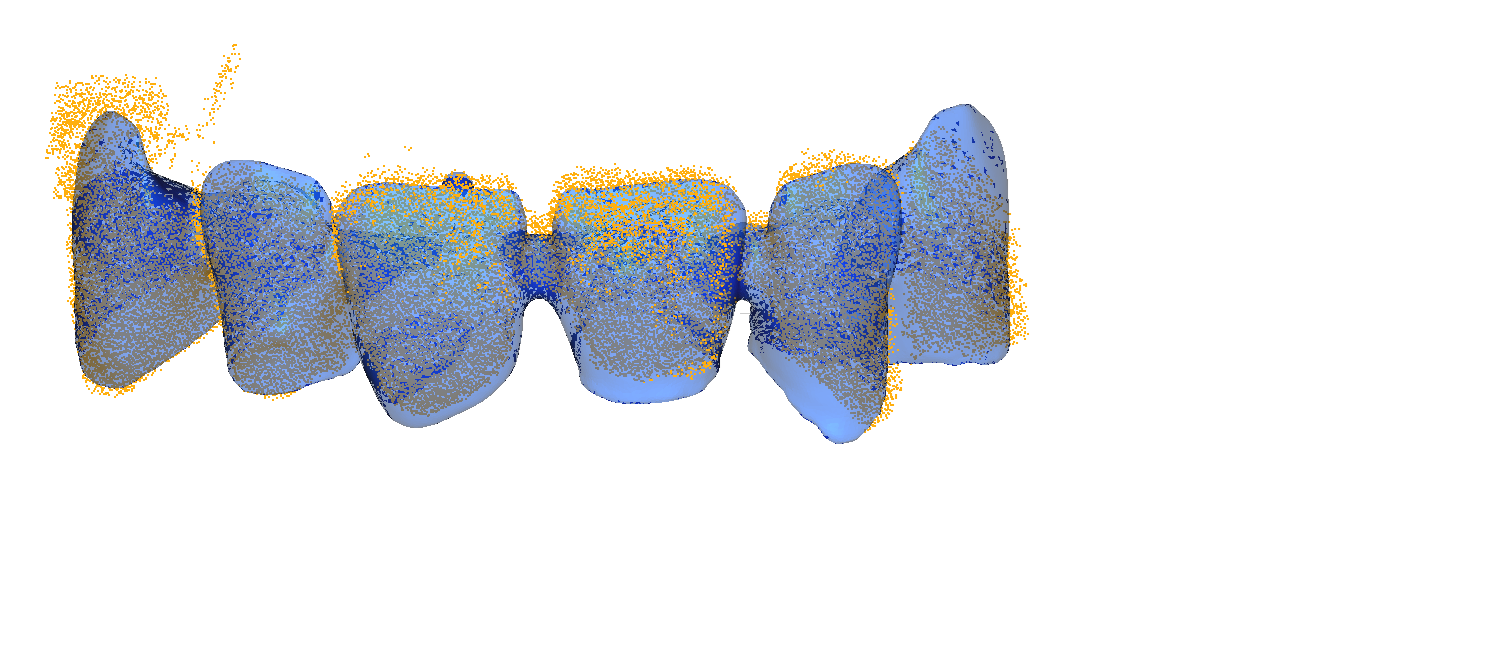

The developed prototype, shows that the use of event-cameras enables a fast, high-resolution

scanner which is suitable for in-line inspection of 3D printed dental implants.

The European subsidized 3DOP project aims to deliver 3D Printing Optimized Products, processes, and services for 3D metal printing, 3D printed moulds with imprinted electronics, automation in the dental industry and 3D Print factories for Industry 4.0.