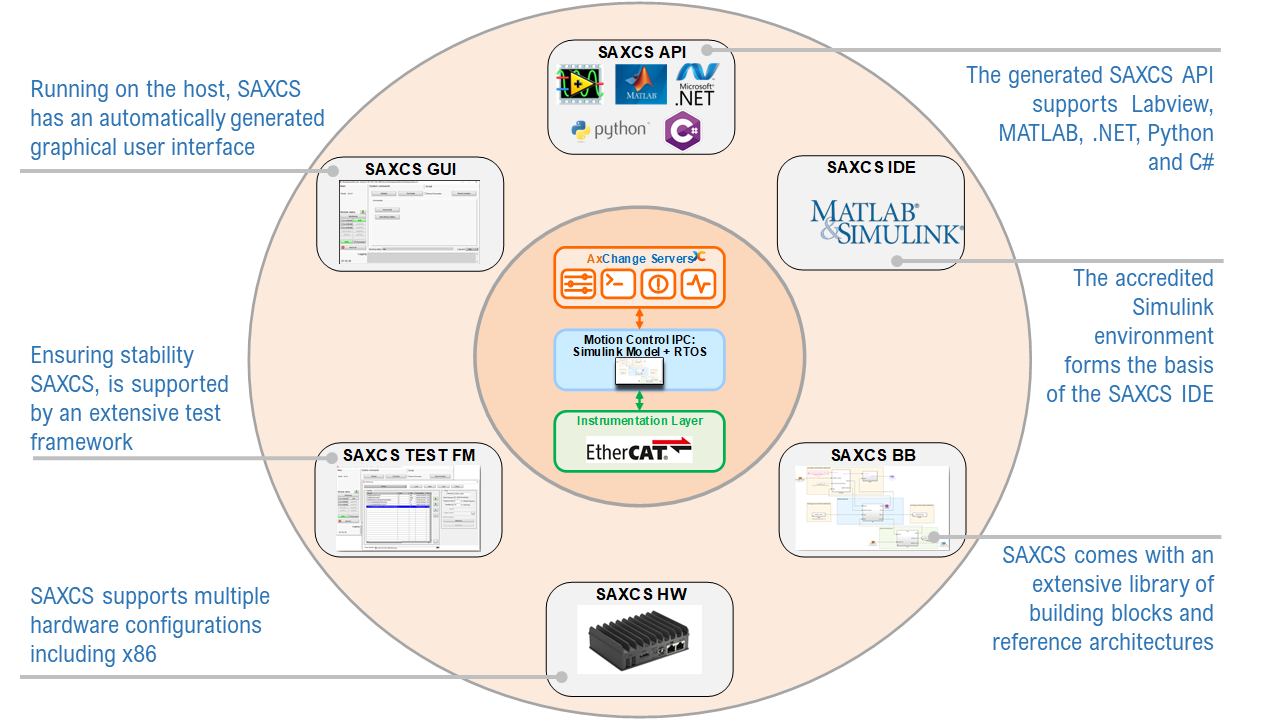

SAXCS is a highly customizable real-time software application for advanced motion control. It enables fast development of cutting-edge high-tech equipment and optimizing production and operations.

High-tech equipment is becoming increasingly complex with cutting-edge mechatronics, intricate sensor systems, many IO and intelligent machine software. Ever stricter requirements concerning performance in speed and accuracy demand a better understanding of the equipment’s physics to successfully implement algorithms for compensation and correcting of position errors. Active in different fields - e.g, medical, semiconductor, analytical - Sioux has been developing equipment for many years. Together with its customers, Sioux experienced the challenges of bringing groundbreaking technology to life. To deal with this, Sioux created SAXCS.

The SAXCS toolchain enables the development of highly customizable real-time software applications for advanced motion control. Among its features are high sample frequencies that enable high controller bandwidths, MIMO control, iterative learning control and setpoint shaping. It connects to system behavior layer via a Sioux proprietary communication framework (AxChange) and the sensor/actuator layer via EtherCAT.

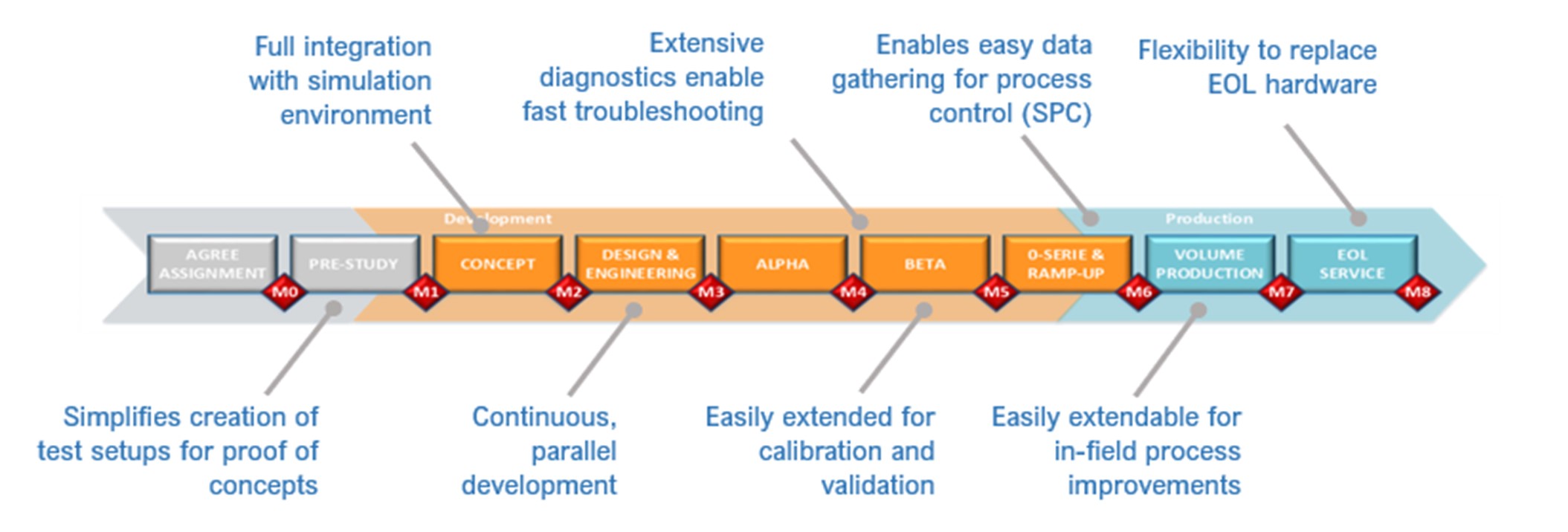

SACXS enables creating motion control software in parallel with the mechanics and electronics development. It facilitates agility, short development cycles and continuous integration without the need for actual hardware. In this way the time to market of equipment can be shortened, while ramping up quality and reducing costs.